Preparations You Should Make Before Subsea Test Tree Application

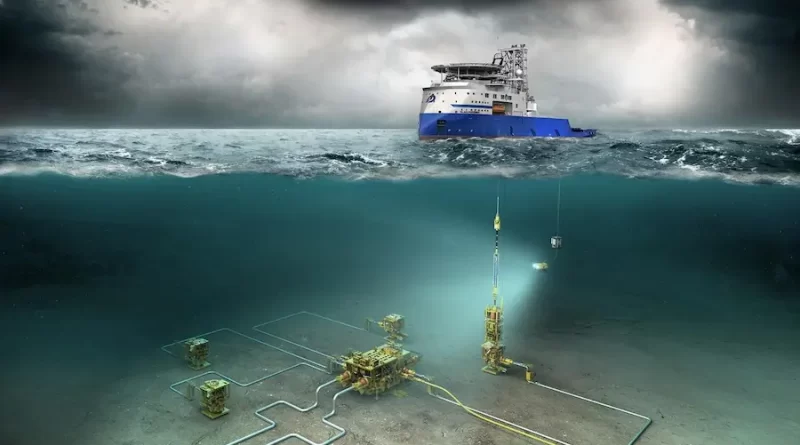

Whether you are considering starting a new subsea test tree application or looking to make some improvements to an existing application, you will want to ensure you are prepared for the project. This is especially true if you operate the test tree in a harsh environment.

Shear rams

Several preparations must be made, just like PRT Offshore subsea completions, before a subsea test tree is applied to a well. These include ensuring that the area is prepared, that the equipment is functional, and that the rig is adequately prepared to support the operation. These preparations will help ensure that the tree will perform its function with minimal interruptions to the well.

The Petrobras EDS system is designed to improve well construction competence. The system includes a program that automates well-construction documentation and a software application that makes it easier to identify the most effective EDS for a particular task. The system was developed as part of a comprehensive solution for EDS 0 that streamlined the excellent construction process.

The best EDS will vary according to the completed well, the rig’s location, the depth of the water, and the type of equipment used. It is best to have accurate dimensional drawings on the rig floor at all times.

Electrohydraulic controls

Traditionally, subsea control systems use hydraulics to control valves. However, the introduction of electro-hydraulic systems has helped to overcome slow response times. In addition, it is possible to analyze and optimize the performance of a system. It also helps to reduce costs.

Electrohydraulic controls can be used for pressure, emergency disconnect functions, and well shut-ins. This system increases efficiency during complicated deepwater completion and landing string operations. In addition, the system eliminates the need for conventional control systems, which require at least one additional umbilical on each excellent zone.

An electrohydraulic control system typically comprises a subsea control module, a hydraulic accumulator, a running tool assembly, and a riser control module. An electrical signal from the surface activates each function. These components are mounted to the subsea tree member.

Hydraulic pressure is supplied to the running tool assembly by the hydraulic accumulator. A communication line connects the running tool assembly to the subsea control module. The subsea control module may be placed on a wellhead with the original completion.

Sensory understanding of what’s happening

Even though we are less than a month away from a flurry of subsea-related activity, there is still plenty of sand to shake a stick at. A top-notch subsea exec can wiggle out the yoosh with aplomb, leaving a lesser mortal a trail of crumbs. Besides, a subsea babe with the kinks and a tad more swag onboard has a better chance of getting a good night’s sleep than her sexy counterpart down at the local dive bar. Those who can’t resist will swoon over the babe. While the babe may not have the monopoly power of the sexy counterpart, she can still take home the trophy of the best mate.

Specifications

Specifying materials for subsea test tree application is an essential step in the design process. The specification includes the requirements for structural components, piping, and corrosion coatings. The material selection process involves considering the performance and cost of the product.

Structural components are commonly structural steels. However, the structural material grade choice should be made based on design requirements. Typically, structural steels are welded. Weldability is also essential.

Tree piping is typically designed following ASME B31.3. The piping includes pressure conduits, produced oil servicing, and injection piping. It excludes chokes and valves. It may be used for production, servicing, and testing.

Tree piping is designed to contain the pressures and flows that are produced. It also includes a choke for the down-hole safety valve. Flow assurance is essential for the subsea tree. Flow assurance requires that the thermal behavior of the subsea tree is appropriate. For this reason, the piping should be thermally insulated.